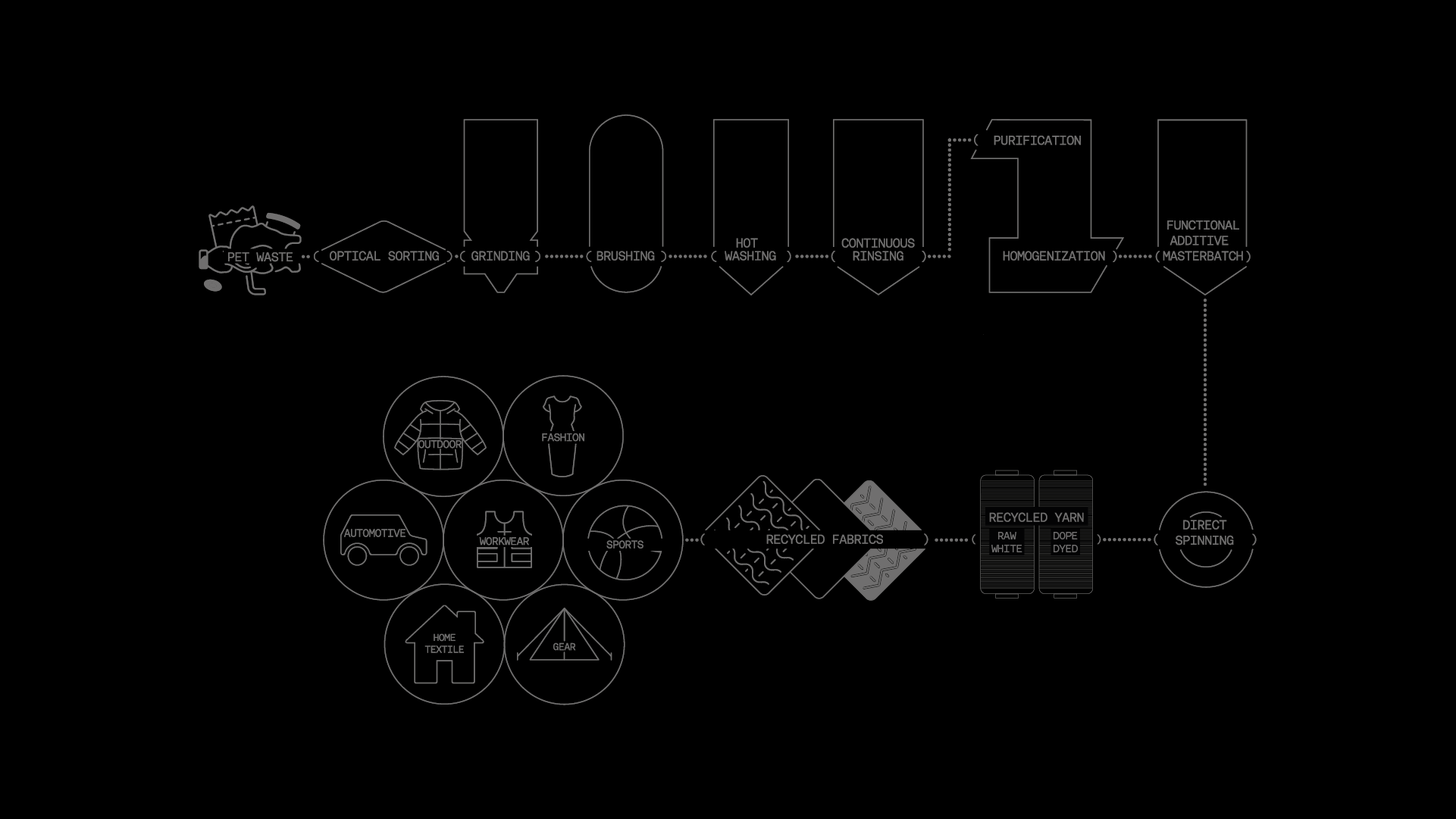

Technology

BioCulus

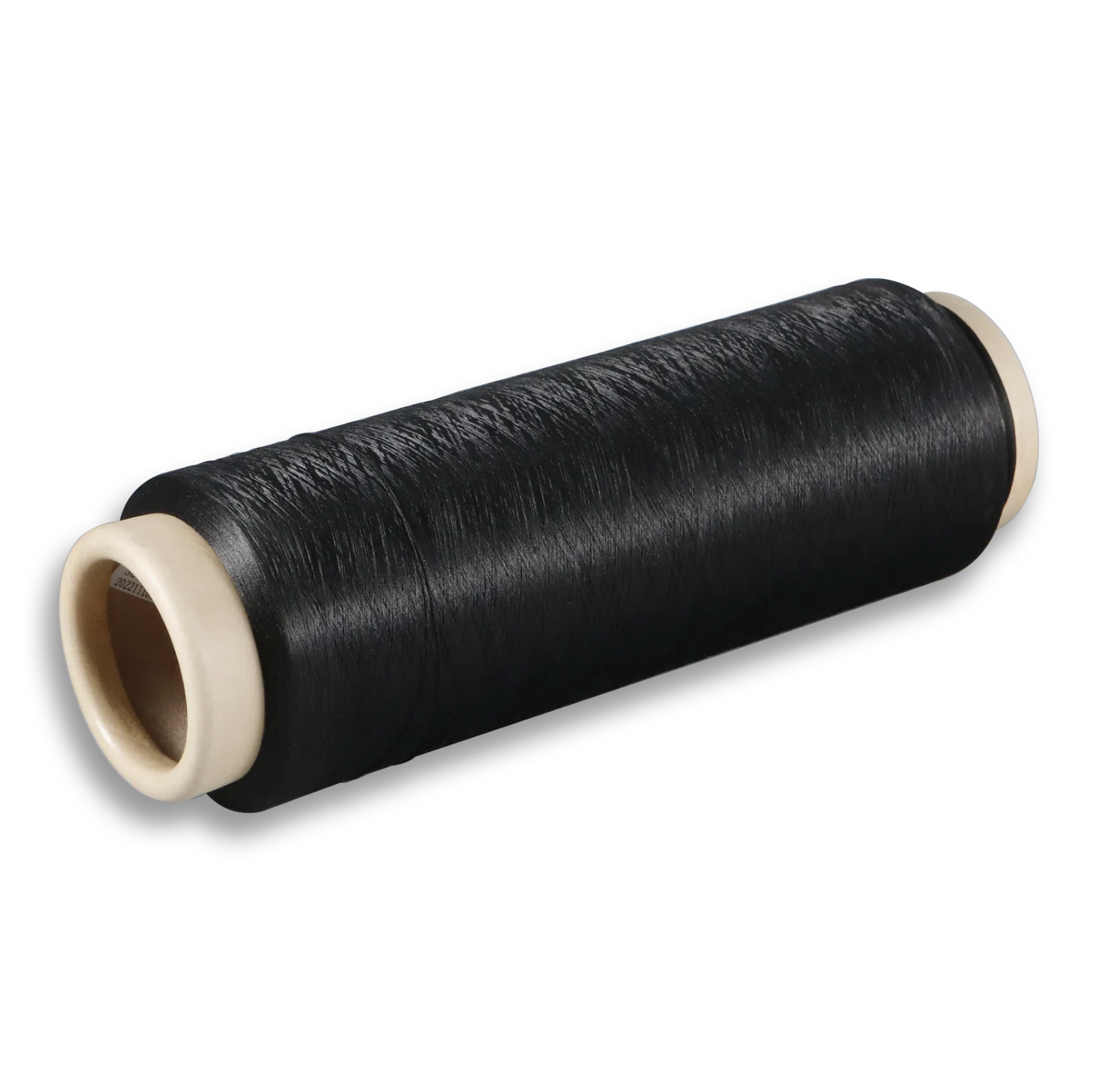

Recycled Dope-Dyed Filament Yarn

Powered by REO-ECO's vertical process with a fixed recipe.

The natural choice for high-quality products, outstanding

performance, and resource savings. Starting with Black.

The natural choice for high-quality products, outstanding

performance, and resource savings. Starting with Black.

Products

+ more

reoYarn →

FDY

DTY

POY

FixDyeYarn →

DOPE_DYED

YARN

reoChips →

BRIGHT

SEMI-DULL

FULL-DULL

iRe-Tech →